|

4 registered members (barnacle, mr_tickle, kaci, 1 invisible),

270

guests, and 3

spiders. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums69

Topics113,600

Posts1,341,113

Members1,802

| |

Most Online731

Jan 14th, 2020

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1575744

Re: front and rear ARB

[Re: hangar1138]

#1575744

02/06/2016 15:10

02/06/2016 15:10

|

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

hangar1138

OP

OP

Making a profit

|

OP

OP

Making a profit

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

|

I think it's not so difficult, material will be the cheaper of the market probably Fe360 sure at 99% remember that resistance to torsion module not depends on type of steel of course I will need to make some tests with different thickness dont think that suppliers of these bars are NASA enginners...  for the beginning I need to know external diameter thickness and bends and after I will try to prepare a prototype https://www.youtube.com/watch?v=cjdOSQ4lbaUin the video the diameter 22x1,2 but the machine can bend up to diameter 30x2

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576120

Re: front and rear ARB

[Re: hangar1138]

#1576120

06/06/2016 13:39

06/06/2016 13:39

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

Hello hangar!

I can ship to you

- UPRATED FRONT BAR (Eibach)

- standard rear bar

To replicate them

Consider that Eibach bar are solid, I think.

You can take measure of the front, calculate volume, and knowing material obtain the answer: hollow or solid tube?

Let me know if you want the bars shipped!

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576133

Re: front and rear ARB

[Re: hangar1138]

#1576133

06/06/2016 16:07

06/06/2016 16:07

|

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

hangar1138

OP

OP

Making a profit

|

OP

OP

Making a profit

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

|

from my calculations: Ø22 solid is has a bending modulus of 1045 mm3 maximum bending capacity of my strongest machine (Ø30x2) 1155 mm3 so we are in range for bends with medium radius greater 1,5 times diameter (22*1,5 = rm 33 mm) about the strenght of the rear arb we are going to design and build: solid Ø22 has a torsional strenght of 2090 mm3 a tube Ø22 and 6 mm ticknes has a torsional strenght of 1893 mm3 so only 9,5 % less than solid Ø22 with tickness 7 we have only 5 % less Gimmo you are very fresh of study ... is all correct ??

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576196

Re: front and rear ARB

[Re: hangar1138]

#1576196

07/06/2016 09:43

07/06/2016 09:43

|

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

hangar1138

OP

OP

Making a profit

|

OP

OP

Making a profit

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

|

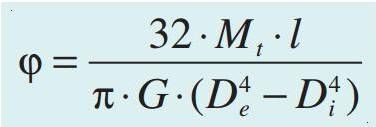

hi Gunzi we are to design at rigidity and not at resistance this is the formula:  where (fi) is the angle of torsion in radiants (1 radiant is around 57°) Mt is the torque in Nm l is the lenght of the bar G is the shear modulus (for the steel is around 81000 N/mm2) De is external diameter Di is internal diameter for the solid bar is enough to put Di=0 remember also that we are in SI (international system of units) and for the formula you have to use Newton meters and the angles are in radiants if we design Øe 22 mm and Øi 8 mm we will have a very small difference in the angle of torsion (fi) but of course always greater than a solid Ø22 the Eibach arb are too expensive, my bars can be easily under 70 € each

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576214

Re: front and rear ARB

[Re: hangar1138]

#1576214

07/06/2016 13:04

07/06/2016 13:04

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

I confirm, but I made calculations taking into account Polar Moment of Inertia of the tubes.

Remanimng

J = Polar Moment of Inertia

Js = J solid tube

Jh = J hollow tube

Dext = external diameter

Dint = internal diameter (equal to Dext - 2*thickness)

pi = 3.1416

solid tube

Js = pi * Dext^4 / 32

Hollow tube

Jh = pi * (Dext^4 - Dint^4) / 32

_ Eibach REAR arb is 23mm, solid tube -> Js_eibach === Js_23 = 27'437 mm4

Whiteline REAR arb is 22mm, solid tube -> Js_whiteline = Js_22 = 22'998 mm4

In case of hollow tube, with thickness equal to 6mm:

Dext = 23mm, Dint = 11mm, hollow tube -> Jh_23 = 26'036 mm4

Dext = 22mm, Dint = 10mm, hollow tube -> Jh_23 = 22'016 mm4

Now we can compare solid vs hollow, eibach vs whiteline vs Hangar

__ Eibach: 23mm, solid --> Js_23 = 27'437 mm4

_ Hangar: 23mm, hollow -> Jh_23 = 26'036 mm4

Less than 5% of difference

Whiteline: 22mm, solid ---> Js_22 = 22'998 mm4

_ Hangar: 22mm, hollow -> Jh_23 = 22'016 mm4

Less than 5% of difference

For material: DNA racing is the only one that declare the material for their bar, http://www.dna-racing.it/#!componenti-grande-punto/c1dnr

It if Fe36

Last edited by Gimmo; 07/06/2016 13:06.

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576217

Re: front and rear ARB

[Re: hangar1138]

#1576217

07/06/2016 13:48

07/06/2016 13:48

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

No problem, the only problem is time  I can prepare all on saturday morning, but I am not sure that I can ship them on saturday, maybe next week  Otherwise, I can take measureas, but I it will be the first attempt for me, so I think that shipping is the best solution

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576243

Re: front and rear ARB

[Re: hangar1138]

#1576243

07/06/2016 18:11

07/06/2016 18:11

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

Good!

And let's make the ARB for our cars!!

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576310

Re: front and rear ARB

[Re: hangar1138]

#1576310

08/06/2016 11:58

08/06/2016 11:58

|

Joined: Dec 2005

Posts: 17,367

Staffordshire

Nigel

Forum veteran

|

Forum veteran

Joined: Dec 2005

Posts: 17,367

Staffordshire

|

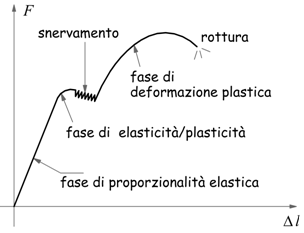

How are you dealing with the method of bending? All the Coupe ARBs I have seen are not crush-bent - there is no reduction in diameter on any of the bends. I have looked at the Mecart tube bending website and it looks like the bends are crush-bent. Your comment that you can't bend solid bar would suggest you can only crush-bend. Surely this will alter the torsional rigidity of the ARB if the cross-sectional area is reduced Also - I understand the very minimal difference between solid bar and tube, but you mention 22mm external diameter and 10mm internal diameter - is this tube readily available with such a large wall thickness? I would have thought that solid would be significantly cheaper. Finally - whilst I applaud the very good intentions behind the thinking on this thread, I have to express a degree of concern. A Coupe with an incorrect ARB is a nightmare to drive. I once had a Whiteline 24mm rear ARB and the car felt like an old-school TVR on ice - it over-steered everywhere. Guessing at dimensions and material can only lead to inaccuracies in the torsional resistance offered by the ARB. I acknowledge your knowledge of materials is far greater than mine, but is it really true that different grades of steel have the same torsion characteristics? I would have thought a high-carbon spring steel would be very different from cheap mild steel Lifted from a discussion on ARBs on another forum:- Mild steel is OK provided you don't put to much twist in the bar which would exceed the elastic limit.

Nearly all steels have quite similar values for Young's modulus that is they are equally stiff or "springy" what varies greatly is the elastic limit ie how far you can deform, stretch, squeeze or twist the steel before its' shape is permanently deformed.

Mild steel has a lower elastic limit than heat treated medium carbon steels (spring steel) but provide the design dosen't twist the anti-roll bar excessively mild steel works just fine. So - have you considered the elastic limits of Coupe ARBs? What is the maximum possible wheel deflection across an axle? Does this exceed the elasticity limit of a low-grade material such as FE36? I wouldn't be bothered if you were making alloy light rings or powder-coated slam panels, but the consequences of a design error on an ARB is that someone ends up on their roof in a field

![[Linked Image]](https://i.imgur.com/19K9lau.jpg)

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576323

Re: front and rear ARB

[Re: hangar1138]

#1576323

08/06/2016 14:06

08/06/2016 14:06

|

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

hangar1138

OP

OP

Making a profit

|

OP

OP

Making a profit

Joined: Apr 2008

Posts: 311

Italy, Reggio Emilia

|

Dear Nigel thanks for all your sharebles worries.. In Mecart we have 2 kind of bends: bend for flexion (on small light tubes) bend for stretching (on big tubes) this are the only 2 way to bend tubes with actual industrial tecnologies of course in every kind of bends you have to exceed the elasticity limit so you have to unnerve a every time the material to keep the new geometry of course 1,5*diameter for the bending radius is a good compromise to not unnerve a lot the external fibers of the steel I cant bend solid Ø22 only because I think it exceed the machine capacity and I'm afraid to break something I agree with you that the results can be different and in some cases it may take to terrible mistakes but we are here with good intention we dont want to force no one to use my arb I will test first and if required I will apply changes to design until I will reach a acceptable result. a better steel will have, true, more resitance at higher torque but the same rigidity of a normal steel

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576330

Re: front and rear ARB

[Re: hangar1138]

#1576330

08/06/2016 15:02

08/06/2016 15:02

|

Joined: Dec 2005

Posts: 17,367

Staffordshire

Nigel

Forum veteran

|

Forum veteran

Joined: Dec 2005

Posts: 17,367

Staffordshire

|

I think we are losing a little in translation here, but as I know no Italian at all, we have to work with each other...  I understand that elasticity limits need to be exceeded to form a bend, but the article I quoted was pointing out that elasticity limits can be exceeded when the ARB is actually fitted to the car if the suspension travel is sufficient (or if the material is sub-standard) Quite simply, on some cars, the twisting of the ARB in normal use could cause the ARB to remain deformed. Repeated application of the torsion force will cause the ARB to fail (with the obvious potential consequences) I note your point about the optimal bend radius being 1.5 * diameter - I think you may need to look closely at the rear ARB - from memory, there are a couple of quit tight bends What about mandrel-bends? - this would retain the external diameter throughout the bend and therefore would not reduce the torsional rigidity

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576332

Re: front and rear ARB

[Re: hangar1138]

#1576332

08/06/2016 15:06

08/06/2016 15:06

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

Nigel, do you know the material of Eibach or Whiteline bar?

The only info I found was on DNA site: Fe36

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576353

Re: front and rear ARB

[Re: hangar1138]

#1576353

08/06/2016 18:57

08/06/2016 18:57

|

Joined: Oct 2008

Posts: 6,783

In the coupe.

magooagain

Club Member 259

|

Club Member 259

Forum is my life

Joined: Oct 2008

Posts: 6,783

In the coupe.

|

Having just watched a whiteline you tube video. It seems that an adjustable arb can be achieved by giving a choice of the amount of the end fixing holes as opposed to just one. By moving it back or forward using the different holes it can raise or lower the torsion. https://m.youtube.com/watch?v=QyMgB4v-tZ8&autoplay=1

Last edited by magooagain; 08/06/2016 19:00.

|

|

|

Re: front and rear ARB

[Re: magooagain]

#1576373

Re: front and rear ARB

[Re: magooagain]

#1576373

08/06/2016 21:22

08/06/2016 21:22

|

Joined: Dec 2005

Posts: 17,367

Staffordshire

Nigel

Forum veteran

|

Forum veteran

Joined: Dec 2005

Posts: 17,367

Staffordshire

|

Having just watched a whiteline you tube video. It seems that an adjustable arb can be achieved by giving a choice of the amount of the end fixing holes as opposed to just one. By moving it back or forward using the different holes it can raise or lower the torsion. https://m.youtube.com/watch?v=QyMgB4v-tZ8&autoplay=1 correct - not exactly rocket science The problem on the Coupe is that the front ARB has single drop-link mount points on the end of the ARB - not much option for different mount points Also, on the rear, the ARB is fixed to the rear radius arms, so adjustability would be "challenging" Can't believe its not possible though

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576452

Re: front and rear ARB

[Re: hangar1138]

#1576452

09/06/2016 13:16

09/06/2016 13:16

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

ARBs ready to be shipped  Note: I understand every doubt, about torsion, rigidity, stiffness etc.. But.. did you evere take on hands, the OEM rear anti roll bar? It is hollow, and very very light! and full of rust! I think is not made by incredible material

|

|

|

Re: front and rear ARB

[Re: ]

#1576461

Re: front and rear ARB

[Re: ]

#1576461

09/06/2016 14:18

09/06/2016 14:18

|

Joined: Dec 2005

Posts: 17,367

Staffordshire

Nigel

Forum veteran

|

Forum veteran

Joined: Dec 2005

Posts: 17,367

Staffordshire

|

Ready to be shipped?  The research & development stage was fairly rapid then....  But.. did you evere take on hands, the OEM rear anti roll bar? It is hollow, and very very light! and full of rust! I think is not made by incredible material  I think my point has been missed.... It doesn't matter how thick or light the original Coupe ARB is - its the effect it has on handling. Unless you have accurately measured the torsional resistance of the original ARB and then produced a new ARB with a known increase in torsional resistance, then you have achieved nothing. Just knowing that the new ARB is "stiffer" is pointless at best and dangerous at worst. Until you have driven a Coupe with a too-stiff rear ARB, you would not believe how dangerous it could be. Think about what lift-off oversteer feels like at 120+ mph - its not fun. So - a simple question - what changes have been made compared with the original ARBs?

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576471

Re: front and rear ARB

[Re: hangar1138]

#1576471

09/06/2016 15:03

09/06/2016 15:03

|

Joined: Dec 2005

Posts: 1,301

Pontefract, West Yorkshire

andyps

My job on the forum

|

My job on the forum

Joined: Dec 2005

Posts: 1,301

Pontefract, West Yorkshire

|

I spoke to these people about roll bars and they said they would be able to make an adjustable one - Cornering Force - the reasons I didn't proceed was that they had a very long waiting list and the cost for a one-off was high. Once one was made subsequent bars would be able to be much cheaper of course.

Andy ![[Linked Image]](http://spa-pa.co.uk/wp-content/uploads/2015/11/wp805-e1448469506809.jpg)

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576473

Re: front and rear ARB

[Re: hangar1138]

#1576473

09/06/2016 15:48

09/06/2016 15:48

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

Remember that DNA racing in italy can make the bars, but they will cost 180euros + vat each one! And they want an order for 30 pieces for bar. Finger cross for hangar work, I can help him sending mine, other I can not do

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1576977

Re: front and rear ARB

[Re: hangar1138]

#1576977

13/06/2016 23:05

13/06/2016 23:05

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

My arb were shipped to hangar today!

|

|

|

Re: front and rear ARB

[Re: hangar1138]

#1577022

Re: front and rear ARB

[Re: hangar1138]

#1577022

14/06/2016 13:52

14/06/2016 13:52

|

Gimmo

Unregistered

|

Gimmo

Unregistered

|

Arb arrived to hangar.

Work can start!

|

|

|

|